Prestress

Prestress is a technique that generates stresses in structural elements before they are loaded. This can be used to reduce particular unwanted stresses and/or displacements which would develop due to external loads, or for generating particular shapes of tension structures.

Prestressing techniques can be used to achieve:

- A redistribution of internal forces: reduction of the maximum internal forces will permit the design of lighter structures.

- Avoidance of cracks: keeping a member in constant compression means that there will be no cracks.

- Stiffening a structure or a structural element.

Model Demonstrations

Prestressed wooden blocks forming a beam and a column

This model demonstrates the effect of prestressing which makes separate wooden blocks act as a beam or column.

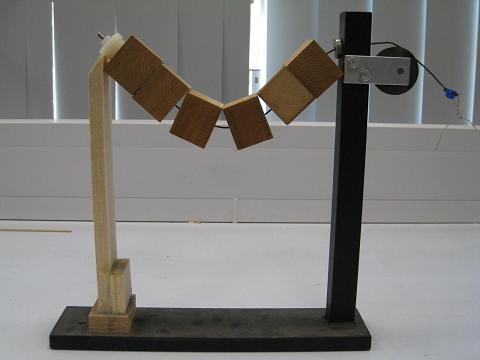

Fig. 11-5: Effect of prestressing (1)

Fig. 11-5a shows a number of separated wooden cubes which are linked using a metal wire through small holes at their centres. One end of the wire passes over a support post while the other end is constrained horizontally by a metal post preventing the cubes from falling down. The structure formed cannot support even its own weight and the cubes simply hang on the wire. If weights are attached to the right hand end of the wire, the wire is tightened. The metal post and the increased compressive prestress between the cubes enable them to form a structure that can now carry an external load as shown in Fig. 11-5b.

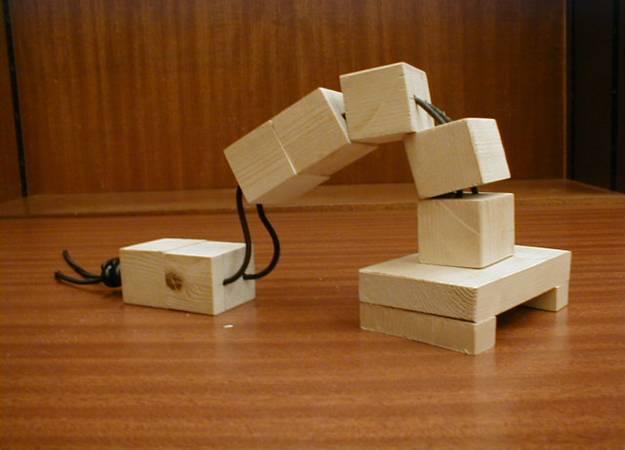

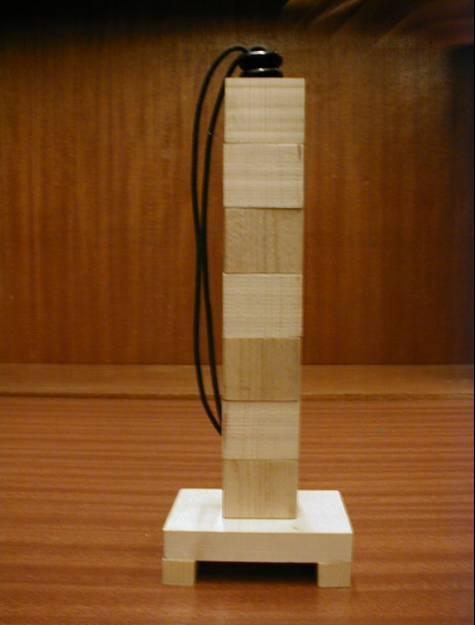

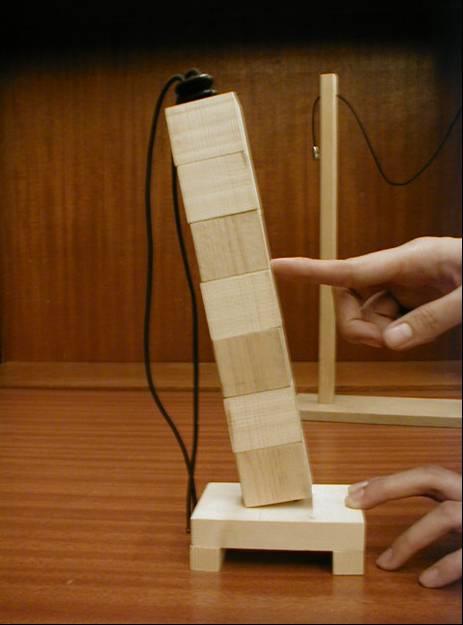

Fig. 11-6: Effect of prestressing (2)

A loose elastic string, with one end fixed to a base, passes through the central holes of a pile of wooden blocks as shown in Fig. 11-6. The effect of prestress can be demonstrated as follows:

- Push the column from one side, it will topple as shown in Fig. 11-6a.

- Reform the column and tighten the elastic string anchoring it to the top block (Fig. 11-6b)

- Hold the base of the model and again push one side of the column. This time the blocks act as a single member which cannot be easily toppled as shown in Fig. 11-6c.

A toy using prestressing

This model demonstrates the effect of tension in strings which makes a toy stable and upright.

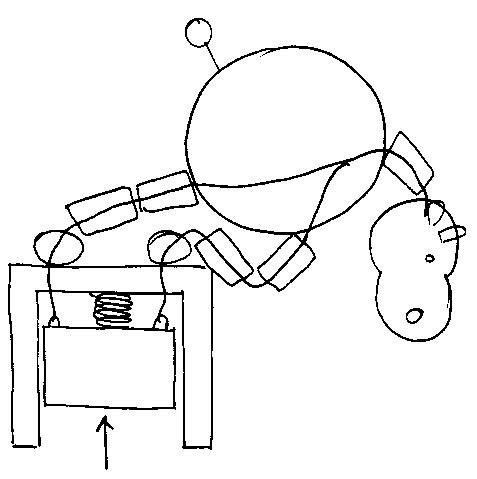

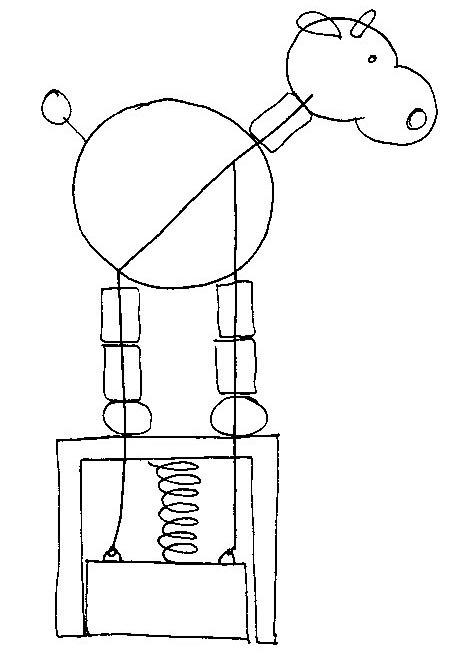

Fig. 11-7: Prestressing used in a toy (Courtesy of Miss G Christian,) [11.6]

A popular toy (Fig. 11-7a) makes use of prestressing. The mechanism for the prestressing is illustrated in Fig. 11-7b and 11-7c.

Strings are threaded through the legs of the toy and attached to the base. A spring is used to push the base down and create tension in the strings to hold the toy upright and stable (Fig. 11-7b).

When the base is pushed upwards, the tension in the string is released. The sections of the legs are no longer held in place and become unstable and the toy collapses (Fig. 11-7c). When the force is released, the spring makes the base move down, the strings become taught and the toy straightens and becomes stable.

Practical Examples

A centrally post-tensioned column

Fig. 11-8 shows three piles of stones which form stone columns in a park. This landmark is similar to the wooden block column model shown in Fig. 11-6. A steel bar, with one end anchored into a foundation below the stones, is threaded through pre-made central holes in the stones. The bar is then tensioned to make the stone blocks act together similar to a single member.

An eccentrally post-tensioned beam

In order to reduce the maximum sagging bending moment of a beam and its maximum deflection when loaded, prestressing can be used to produce initial hogging bending moments and upward deflections, which will offset parts of the bending moments and deflections induced by the subsequent downward vertical loading.

To produce a hogging bending moment and upward deflection of a beam, the post-tensioned steel bar needs to be placed below the neutral axis of the cross-section of the beam. The position of the tendon should be as low as possible to produce larger hogging moments and deflections or to allow smaller post-tension forces.

Fig. 11-9 shows a composite beam that has a span of over 10 m [11.7]. The cross-section of the beam is T shaped and the post-tensioning tendon is placed at a position much lower than the neutral axis of the section.

Spider’s web

Fig. 11-10: Spider’s webs (Courtesy of Dr ASK Kwan, Cardiff University)

Spiders have been able to produce silk for the last 400 million years and have been building orb webs for the last 180 million years. The webs have evolved to arrest the flight and capture fast moving and relatively large insects [11.8, 11.9]. Fig. 11-10 shows two spiders’ webs that consist of radial threads, capture spirals and anchor threads.

The anchor threads span from the supports and suspend the radial threads. The radial threads are then overlaid by the sticky capture spirals. The prestressing is applied during construction by simply pulling the individual strands tighter around their supports.

A cable-net roof

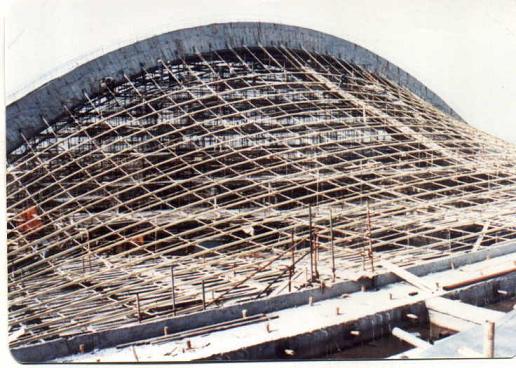

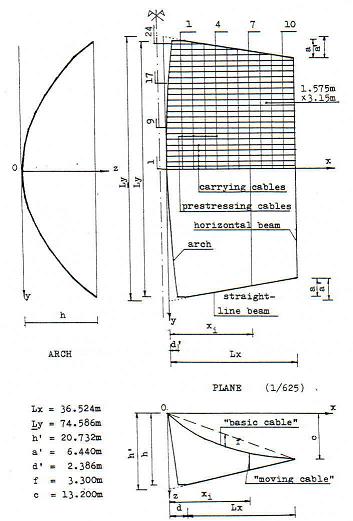

Fig. 11-11: Cable net roof of the Sichuan Provincial Gymnasium

Cable-net roofs are ideally suited for use with long span structures such as gymnasia. Fig. 11-11a shows half of the cable-net roof used for the Sichuan Provincial Gymnasium, which was built in 1988 and is able to contain over 10,000 seated spectators [11.10].

The stiffness of the cable-net roof was established by prestressing. By applying forces at the ends of prestressing (hogging) cables, tension forces are induced in both carrying (sagging) cables and prestressing cables. The prestressing and carrying cables are normally placed perpendicularly to each other (Fig. 11-11b). The level of prestress applied should ensure that no prestressing cables are slack for any load configuration.

References

11.1 Hemera Technologies, (2001), Photo-Objects 50,000 Volume 2, Canada.

11.2 Lin, T Y, (1955), Design of Prestressed Concrete Structures, John Wiley & Sons, New York.

11.3 Nawy, E G, (1995), Prestressed Concrete, A Fundamental Approach, Second Eddition, Prentice-Hall, New Jersey, ISBN 0 13 123480 3

11.4 Buchholdt, H A, (1985), Introduction to Cable Roof Structures, Cambridge University Press, Cambridge, ISBN 0521 30263 3.

11.5 Lewis, W J, (2003), Tension Structures: Form and Behaviour, Thomas Telford, London, ISBN 0 7277 3236 6.

11.6 Ji, T and Bell, A J, (2007), Enhancing the understanding of structural concepts – a collection of students’ coursework, The University of Manchester.

11.7 Bailey, C G, Currie, P M and Miller F R, (2006), Development of a new long span composite floor system, The Structural Engineer, Vol. 84, No. 21, pp. 32-38

11.8 Lin, L H, Edmonds, D T and Vollrath F, (1995), Structural engineering of an orb-spider’s web, Nature, Vol. 373, pp. 146-168.

11.9 Ji, T, (2001), Cable Structures – a collection of students’ coursework, UMIST.

11.10 Ji, T., (1986), Design and analysis of orthogonal cable-net roofs with complex shapes, Proceedings of International Symposium on Membrane Structures and Space Frames, Vol.2, Japan.