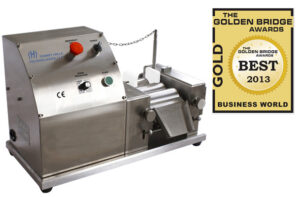

Three roll mill

A Three Roll Mill has three horizontally positioned rollers. Each roller rotates in an opposite direction from the adjacent roller with a tiny gap between them, creating tremendous shear force that can finely disperse, mix, refine or homogenize viscous materials. They are widely used to mix electronic thick film inks, high performance ceramics, cosmetics, plastisols, carbon/graphite, paints, printing inks, pharmaceuticals, chemicals, glass coatings, dental composites, pigment, coatings, adhesives, sealants, and foods. The material is loaded between the feeder roll and the center roll. Due to the narrowing space between the rolls, most of the mixture is rejected to the feed region. The part does make it through experiences very high shear force and disperses the pigment particles in the binder. As it comes out the other side, the material that remains on the center roll moves through to nip between the center roll and apron roll, experiencing even high shear force due to the higher speeds. A blade automatically scrapes the processed mixture off the apron roll transfers it to the apron. The three roll milling cycle is repeated many times until the material is perfectly dispersed and the particle size is in the good range.

A Three Roll Mill has three horizontally positioned rollers. Each roller rotates in an opposite direction from the adjacent roller with a tiny gap between them, creating tremendous shear force that can finely disperse, mix, refine or homogenize viscous materials. They are widely used to mix electronic thick film inks, high performance ceramics, cosmetics, plastisols, carbon/graphite, paints, printing inks, pharmaceuticals, chemicals, glass coatings, dental composites, pigment, coatings, adhesives, sealants, and foods. The material is loaded between the feeder roll and the center roll. Due to the narrowing space between the rolls, most of the mixture is rejected to the feed region. The part does make it through experiences very high shear force and disperses the pigment particles in the binder. As it comes out the other side, the material that remains on the center roll moves through to nip between the center roll and apron roll, experiencing even high shear force due to the higher speeds. A blade automatically scrapes the processed mixture off the apron roll transfers it to the apron. The three roll milling cycle is repeated many times until the material is perfectly dispersed and the particle size is in the good range.

Shear Mixer

The latest development in high shear lab mixing – the new Silverson L5M-A – is ideal for all laboratory work, research and development, QA analysis and small scale production in all industries. The L5M-A Laboratory Mixer is suitable for the widest range of applications – mixing, emulsifying, homogenizing, disintegrating and dissolving – with an efficiency and flexibility unmatched by other machines. With a capacity from 1ml up to 12 liters and the ability to mix in-line with flow rates up to 20 liters/minute, they offer excellent reproducibility when scaling up to full-scale production and provide an accurate and easy means of forecasting the performance of larger Silverson machines under full-scale working conditions. The multifunctional L5M-A lab mixer features touch screen control with digital tachometer, programmable integral timer and amperage display. This level of instrumentation is invaluable for applications where process validation and reproducibility are required. Over 40 interchangeable mixing assemblies are available for L5 Series Laboratory mixers. The unit is finished in a tough, easy to clean, non-chip white nylon coating. All wetted parts are in 316L stainless steel with the exception of the bush which may be bronze alloy or PTFE. The mixing unit may be effortlessly raised and lowered using the touch pad control, which offers increased cleanliness and reliability.

The latest development in high shear lab mixing – the new Silverson L5M-A – is ideal for all laboratory work, research and development, QA analysis and small scale production in all industries. The L5M-A Laboratory Mixer is suitable for the widest range of applications – mixing, emulsifying, homogenizing, disintegrating and dissolving – with an efficiency and flexibility unmatched by other machines. With a capacity from 1ml up to 12 liters and the ability to mix in-line with flow rates up to 20 liters/minute, they offer excellent reproducibility when scaling up to full-scale production and provide an accurate and easy means of forecasting the performance of larger Silverson machines under full-scale working conditions. The multifunctional L5M-A lab mixer features touch screen control with digital tachometer, programmable integral timer and amperage display. This level of instrumentation is invaluable for applications where process validation and reproducibility are required. Over 40 interchangeable mixing assemblies are available for L5 Series Laboratory mixers. The unit is finished in a tough, easy to clean, non-chip white nylon coating. All wetted parts are in 316L stainless steel with the exception of the bush which may be bronze alloy or PTFE. The mixing unit may be effortlessly raised and lowered using the touch pad control, which offers increased cleanliness and reliability.

Sonicator

The new Q700 is the most technologically advanced sonicator available today. A state-of-the-art touch screen interface offers intuitive control and provides a user-friendly experience. The most important feature of a Sonicator is reproducibility. Improved internal circuitry guarantees more efficient operation, sample-to-sample consistency and most importantly, a reliable end result. The Q700 is the only sonicator on the market that offers full amplitude control from 1-100%. This enables greater control of the probe’s intensity, helping to pinpoint the optimum settings for efficient sample processing. We have increased maximum power output to 700 watts making the system more durable and capable of handling even larger samples if necessary. Our new display, design improvements and added accessories make this the most sophisticated and versatile Sonicator available today. Part #Q700 includes a standard ½” diameter probe with replaceable tip. A variety of probe/horn options are available and the system can be purchased without the standard probe by selecting #Q700A.

The new Q700 is the most technologically advanced sonicator available today. A state-of-the-art touch screen interface offers intuitive control and provides a user-friendly experience. The most important feature of a Sonicator is reproducibility. Improved internal circuitry guarantees more efficient operation, sample-to-sample consistency and most importantly, a reliable end result. The Q700 is the only sonicator on the market that offers full amplitude control from 1-100%. This enables greater control of the probe’s intensity, helping to pinpoint the optimum settings for efficient sample processing. We have increased maximum power output to 700 watts making the system more durable and capable of handling even larger samples if necessary. Our new display, design improvements and added accessories make this the most sophisticated and versatile Sonicator available today. Part #Q700 includes a standard ½” diameter probe with replaceable tip. A variety of probe/horn options are available and the system can be purchased without the standard probe by selecting #Q700A.